Transforming Efficiency in Paint Manufacturing with the Pigging System Paint Solution

In the world of industrial paint manufacturing, efficiency, cleanliness, and product recovery are essential. With rising production costs, tighter environmental regulations, and growing demand for consistent product quality, manufacturers are turning to advanced technologies to stay competitive. One such innovation is the pigging system paint solution—a highly effective method for recovering product from pipelines, reducing waste, and improving line cleanliness during product changeovers.

This article explores how the pigging system paint process works, why it is increasingly adopted in modern paint production facilities, and the many operational benefits it offers.

What Is a Pigging System?

Before diving into the specifics of the pigging system paint application, it’s essential to understand what a pigging system is. Pigging is a process that involves sending a device called a “pig” through a pipeline to recover product, remove residue, or clean the inner pipe surface. These pigs are typically made of soft, flexible materials like silicone or rubber and are designed to fit tightly inside the pipe to push out liquids as they move.

In the context of paint production, the pigging system paint setup allows manufacturers to recover high-value paint formulations, reduce color contamination between batches, and minimize the need for time-consuming cleaning processes.

See also: AI Face Swap Technology for Creating Alternate Endings in Movies

Why the Paint Industry Needs Pigging

Paint production often involves the handling of highly viscous and color-sensitive liquids. Each color or formulation processed through the same pipeline increases the risk of cross-contamination. Traditionally, manufacturers flushed pipelines with large amounts of solvent or water to clean the system between product runs—this led to excessive waste, time delays, and environmental concerns.

The pigging system paint solution solves these challenges by:

- Efficiently pushing residual paint out of the pipeline for recovery.

- Reducing the amount of flushing agent needed.

- Enabling faster product changeovers without compromising quality.

How the Pigging System Paint Technology Works

The basic principle of the pigging system paint process is to use a pig to physically separate products within a pipeline and push the residual material to its destination. Here’s how the system generally operates in a paint factory:

1. Pig Insertion

A pig is loaded into the pipeline at a launcher station. This can be done manually or automatically, depending on the system’s level of sophistication.

2. Product Transfer

Paint is pumped through the pipeline as normal during production. Once the transfer is complete, instead of leaving residual paint in the line or flushing it out, the pigging process begins.

3. Pig Propulsion

A pushing medium—usually compressed air or nitrogen—is applied behind the pig. This forces the pig through the pipeline, pushing the remaining paint ahead of it. Reliable equipment is critical at this stage, and many facilities rely on a Kaeser air compressor to deliver the consistent pressure needed. This stable airflow forces the pig through the pipeline, efficiently pushing the remaining paint ahead of it.

4. Product Recovery

The remaining paint is recovered and sent to its final destination—such as a mixing tank, storage vessel, or filling line—resulting in virtually no loss.

5. Pig Removal or Return

Once the pig reaches the receiver station, it is either removed or automatically returned to its starting position for the next cycle.

This entire cycle can be completed in a few minutes and is often fully automated in modern installations.

Benefits of Pigging System Paint Applications

✅ High Product Recovery

One of the most significant advantages of using a pigging system paint solution is the ability to recover nearly all paint left in the pipeline. Depending on the pipeline length and diameter, this can amount to several liters—or even gallons—of product saved per run.

✅ Reduced Flushing and Cleaning

With pigging, the need for large volumes of cleaning solvents is dramatically reduced. This not only saves money but also helps minimize environmental impact and operator exposure to chemicals.

✅ Color Change Efficiency

For facilities that frequently switch between colors or formulations, pigging systems allow faster transitions with minimal risk of cross-contamination. This leads to increased uptime and greater flexibility in scheduling production runs.

✅ Improved Hygiene and Quality

Pigging helps remove residue that could affect future batches, ensuring a clean, consistent product output. This is especially critical when manufacturing specialized or premium paint formulations.

✅ Environmental and Sustainability Benefits

By reducing waste, flushing chemicals, and cleaning time, pigging system paint applications align with sustainability goals and help facilities meet regulatory requirements.

Common Paint Types Benefiting from Pigging

Not all paint products are the same, but most can benefit from pigging. Here are some examples:

- Water-based paints: Often used in residential and commercial applications.

- Solvent-based paints: Require tight controls on contamination and residue.

- Industrial coatings: High-value products benefit greatly from product recovery.

- Color concentrates: Pigging prevents color carry-over and ensures quality.

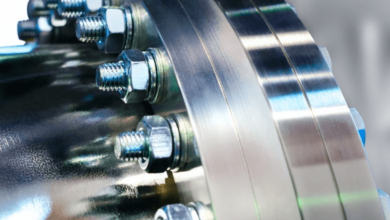

Key Components of a Pigging System in Paint Lines

A typical pigging system paint setup includes the following:

- Pig Launcher and Receiver: Devices to insert and retrieve pigs from the pipeline.

- Piggable Valves: Special full-bore valves that allow the pig to pass through freely.

- Pipeline: Smooth, consistent-diameter piping that ensures effective pig movement.

- Pigs: Often color-coded for different paint lines and made from high-durability elastomers.

- Control System: PLC or SCADA systems to automate the pigging sequence and monitor pig location.

Considerations for Paint Manufacturers

Before implementing a pigging system paint solution, manufacturers should assess several factors:

- Pipeline Compatibility: Older or irregular pipelines may need modification.

- Product Viscosity: Some thicker paints may require specialized pigs or pushing media.

- Color Change Frequency: More frequent changes benefit most from pigging.

- Cost-Benefit Analysis: Consider long-term savings versus initial setup cost.

Conclusion

The pigging system paint technology is revolutionizing how paint manufacturers handle product transfer, cleaning, and recovery. With its ability to minimize waste, speed up changeovers, and improve product quality, pigging is an essential investment for any forward-thinking paint production facility.

As environmental pressures and market competition continue to grow, solutions like pigging not only save money but also help businesses align with sustainability goals and customer expectations. For any manufacturer in the paint industry, now is the right time to consider how pigging can deliver long-term operational benefits.