CNC Turning Parts: The Unsung Heroes of Modern Manufacturing

In the world of manufacturing, there are countless processes that contribute to the creation of the tools, machines, and devices we use every day. One of the most vital but often overlooked components in this ecosystem is CNC turning parts—precisely machined components created through automated turning processes. Found in everything from cars and airplanes to medical devices and consumer electronics, these parts are the building blocks of high-performance, high-precision engineering.

With technology evolving at a breakneck pace, the role of CNC turning parts has become even more essential. Industries now demand tighter tolerances, faster production cycles, and increased reliability—requirements that CNC machining, particularly turning, is uniquely suited to fulfill.

In this article, we’ll explore what CNC turning is, what types of parts it produces, where those parts are used, and why they are so critical to virtually every sector of the modern economy.

What Are CNC Turning Parts?

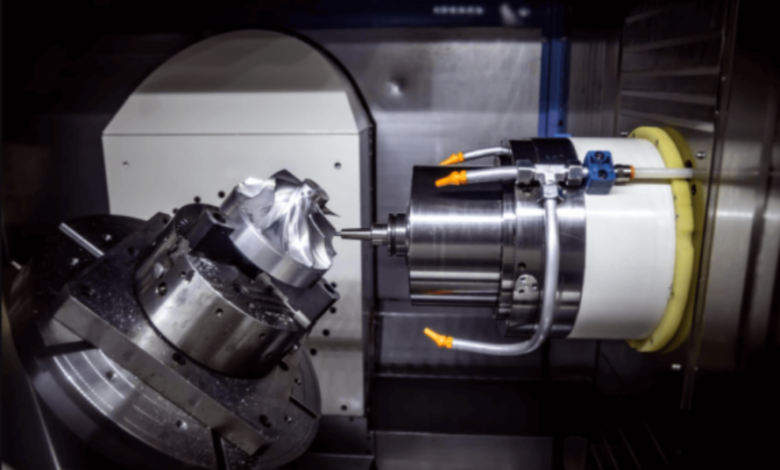

CNC turning parts are components that are shaped using a computer-controlled lathe. The process involves rotating a solid workpiece (often a metal or plastic rod) at high speeds while a cutting tool precisely removes material to form the desired shape.

Unlike traditional lathe turning, CNC turning is automated through software instructions (G-code), which ensures unparalleled accuracy, repeatability, and efficiency. These parts are typically cylindrical or rounded in shape but can include intricate grooves, tapers, threads, and more, thanks to advancements in tooling and multi-axis machinery.

See also: How Technology is Transforming Logistics in Hong Kong

Common Types of CNC Turning Parts

CNC turning can produce a wide variety of parts used in numerous industries. Here are some of the most common types of CNC turning parts:

🔩 Shafts

Used in motors, gearboxes, and engines, shafts must meet strict tolerance and balance requirements to function properly under stress.

⚙ Bushings and Bearings

These are essential for minimizing friction in moving parts and require exceptional roundness and surface finishes.

🧰 Pins and Dowels

Often used for alignment and support in assemblies, pins require uniform dimensions for consistency and interchangeability.

🧵 Threaded Components

Turned parts with internal or external threads are common in hydraulic systems, fasteners, and valves.

🚿 Housings and Caps

Used in plumbing, oil & gas, and automotive applications, these components often involve complex geometries and tight sealing tolerances.

🛠 Custom Prototypes

Engineers frequently use CNC turning to produce one-off or low-volume custom parts during the R&D and prototyping stages.

Materials Used in CNC Turning Parts

One of the strengths of CNC turning is its versatility when it comes to materials. Depending on the application, CNC turning parts can be made from:

- Stainless Steel: Corrosion-resistant and strong, ideal for medical, food-grade, and outdoor components.

- Aluminum: Lightweight, machinable, and affordable, perfect for aerospace and automotive industries.

- Brass: Great for plumbing, decorative elements, and electronic connectors due to its electrical conductivity.

- Titanium: High strength-to-weight ratio and biocompatibility, making it suitable for aerospace and surgical components.

- Plastics: Nylon, PEEK, Delrin, and other polymers are used in electronics, automotive interiors, and consumer goods.

Industries That Rely on CNC Turning Parts

CNC turning parts have applications across nearly every sector of manufacturing. Here are a few industries where these components are critical:

🚗 Automotive

From fuel injectors and engine components to axle shafts and sensor housings, the automotive industry relies heavily on CNC turned parts for both performance and safety.

🛩 Aerospace

Lightweight yet durable components such as airframe connectors, hydraulic fittings, and turbine shafts are typically produced through CNC turning.

🏥 Medical Devices

Surgical instruments, implants, and device enclosures are made with extremely tight tolerances and smooth finishes, which CNC turning can deliver.

⚙ Industrial Machinery

Large-scale manufacturing machinery, conveyors, and robotics all use precision-turned shafts, rollers, and couplings.

🌿 Agriculture and Construction

Tractors, harvesters, and earth-moving equipment depend on rugged turned parts like bushings, hydraulic pins, and spindles.

Why CNC Turning Parts Matter

The importance of CNC turning parts goes far beyond their individual function. These components contribute to the overall quality, durability, and efficiency of the systems they are part of. Here’s why they matter so much:

✅ Precision and Consistency

Because CNC turning is a computer-controlled process, it offers unmatched precision and consistency across production runs. This is crucial for parts that must fit or move perfectly within assemblies.

✅ Scalability

CNC turning is suitable for both small batch prototyping and high-volume production. Once the program is set up, parts can be produced quickly and repeatedly with little variation.

✅ Cost Efficiency

Though initial setup and tooling can be expensive, the per-unit cost of CNC turning drops significantly at scale, making it a cost-effective option for many manufacturers.

✅ Reduced Waste

Modern CNC turning machines optimize material usage and minimize waste, both reducing costs and supporting sustainable manufacturing practices.

✅ Speed to Market

Thanks to automation and digital integration, companies can move from CAD file to final part quickly—reducing lead times and speeding up product development.

Tips for Sourcing High-Quality CNC Turning Parts

If you’re looking to outsource your machining or need reliable suppliers of CNC turning parts, here’s what to consider:

🏭 Manufacturer’s Capabilities

Does the vendor have multi-axis CNC lathes? Can they handle complex geometries and a range of materials?

📐 Tolerance Requirements

Always clarify tolerance specifications and make sure your supplier can meet them consistently.

📦 Order Volumes

Ensure your supplier can handle both prototyping and scale-up for production.

Final Thoughts

Though often hidden inside engines, devices, or behind panels, CNC turning parts are truly the unsung heroes of modern engineering. Their accuracy, durability, and scalability make them indispensable in nearly every manufacturing sector.

From the simplest metal pin to the most complex aerospace component, CNC turning empowers companies to bring ideas to life with precision and speed. Whether you’re a product designer, a purchasing manager, or a manufacturing engineer, understanding the importance of CNC turning parts can help you make smarter, more efficient decisions that support long-term success.